WDMS250 Hybrid digital printer

| Model | WDMS250-16A+ | WDMS250-32A++ | |

| Printing configuration | Printead | Industrial mirco-piezo printhead | |

| Printead qty | 16 | 32 | |

| Printing width | Multi-pass :2500mm Single-pass :520mm |

||

| Ink type | Special water-based dye ink, special water-based pigment ink | ||

| Ink color | Sandard:Cyan,Magenta,Yellow,Black Optional:LC,LM,PL,OR |

||

| Ink supply | Automatic ink supply | ||

| Operation system | Professional RIP system,professional printing sy stem, Win10/11 system with 64 bit operating system or above |

||

| Input format | JPG,JPEG,PDF,DXF,EPS,TIF,TIFF,BMP,AI,etc. | ||

| Efficiency | Single-pass | 200*600dpi,max 1.8m/s; 300*600dpi,max 1.3m/s; 600*600dpi,max 0.65m/s; |

200*1200dpi时,max 1.8m/s; 300*1200dpi时,max 1.3m/s; 600*1200dpi时,max 0.65m/s; |

| Multi-pass | 300*600dpi, max 1400㎡/hour |

300*600dpi, max 1400㎡/hour |

|

| Printing material | Application | All kinds of corrugated cardboard (yellow and white cattle board, honeycomb board, etc.), available to print semi-coated board with dryer | |

| Max width | 2500mm | ||

| Min width | 560mm | ||

| Max length | 2200mm under auto feeding,no limit under manual feeding(Cardboard stack weight affects autofeed length) | ||

| Min length | 420mm | ||

| Thickness | 1.2mm-25mm | ||

| Feeding system | Automatic leading edge feeding, suction platform | ||

| Working environment | Workplace Requirements | Install compartment | |

| Temperature | 20℃-25℃ | ||

| Humidity | 50%-70% | ||

| Power supply | AC380±10%,50-60HZ | ||

| Air supply | 8kg-8kg | ||

| Power | About 22KW | ||

| Others | Machine size | 5545*6150*2032 (mm)with shell 5255*5835*1700(mm)without shell |

|

| Machine weight | 5300KGS with cover 4350KGS without cover |

||

| Optional | Variable data,ERP docking port | ||

| Voltage stabilizer | The voltage stabilizer needs to be self-configured,request 80KW | ||

| Features | New | Technological innovation, multi-pass scanning and Single-pass high speed printing are integrated | |

| Advantage | WDMS250 Hybrid digital printerWDMS250 combines two different digital printing methods: Multi Pass high-precision scanning and Single Pass high-speed printing. You can choose to use the scanning mode to print large-size, large-area, high-precision, full-color carton orders, or instantly Switch to Single pass high-speed mode to print large quantities of orders to meet a wider range of corrugated digital printing needs, covering more than 70% of customer groups, reducing equipment investment, saving space, labor, maintenance and other costs, and greatly improving production efficiency. Another innovation in digital printing technology! |

||

| Features of digital printer (common to all printer) | Revolutionary in world Inkjet technology Print on demand No limit with quantity Variable data ERP docking port Quick-done ability Computer color correction Simple process Easy operation Labor saving No composition change No machine cleaning Low-carbon & environment Cost-effective |

||

Features of digital printer (common to all printer)

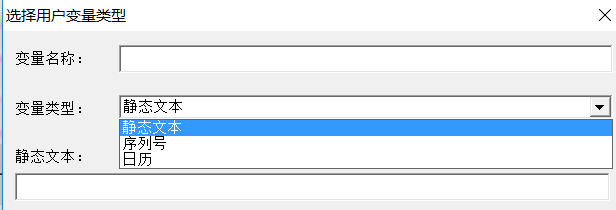

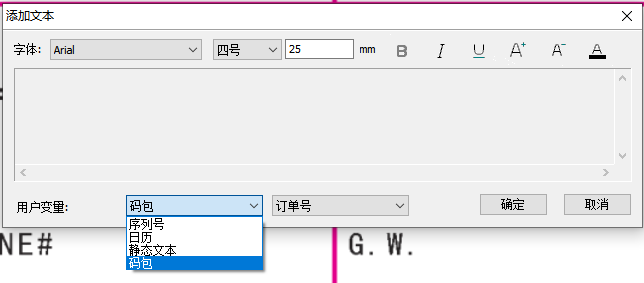

Variable data

Text variable

Sequence: It can be changed according to user definition, and the set sequence can also be used for variable barcode

Date: Print date data and support custom changes, the set date can also be used for variable barcodes

Text: The text data entered by the user is printed, and the text is generally only used when the mode is text data

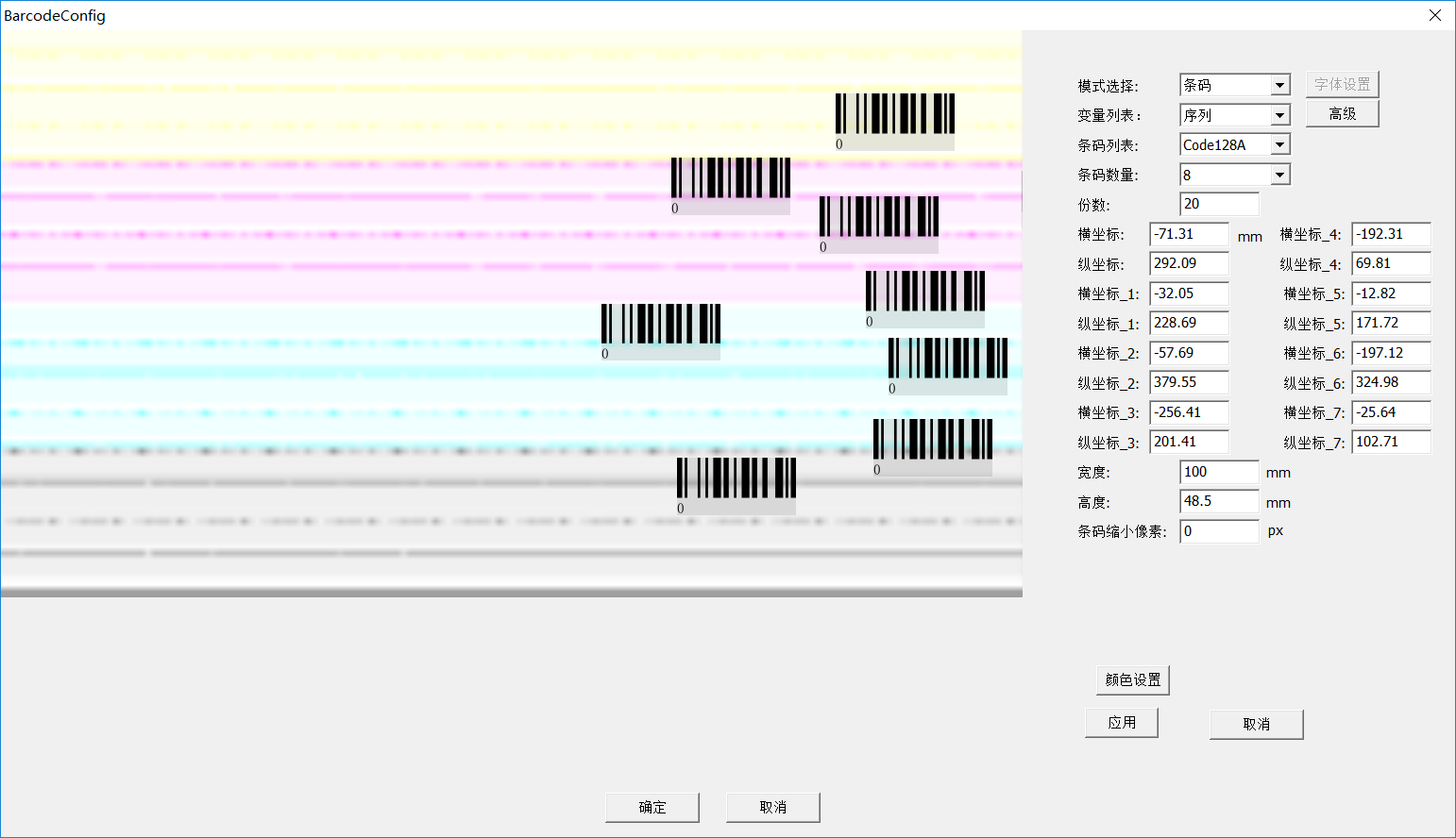

Bar code variable

The current mainstream barcode types can be applied

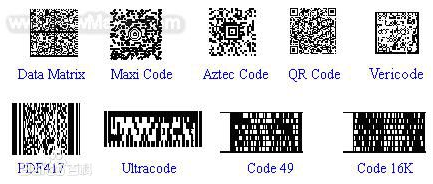

QR code variable

Among the dozens of 2D barcodes at present, the commonly used code systems are: PDF417 2D barcode, Datamatrix 2D barcode, Maxcode 2D barcode. QR Code. Code 49, Code 16K, Code one., etc. In addition to these common two In addition to dimensional barcodes, there are also Vericode barcodes, CP barcodes, CodablockF barcodes, Tianzi barcodes, UItracode barcodes, and Aztec barcodes.

Code package variable

Including: text, barcode, QR code can realize multiple variables on one carton

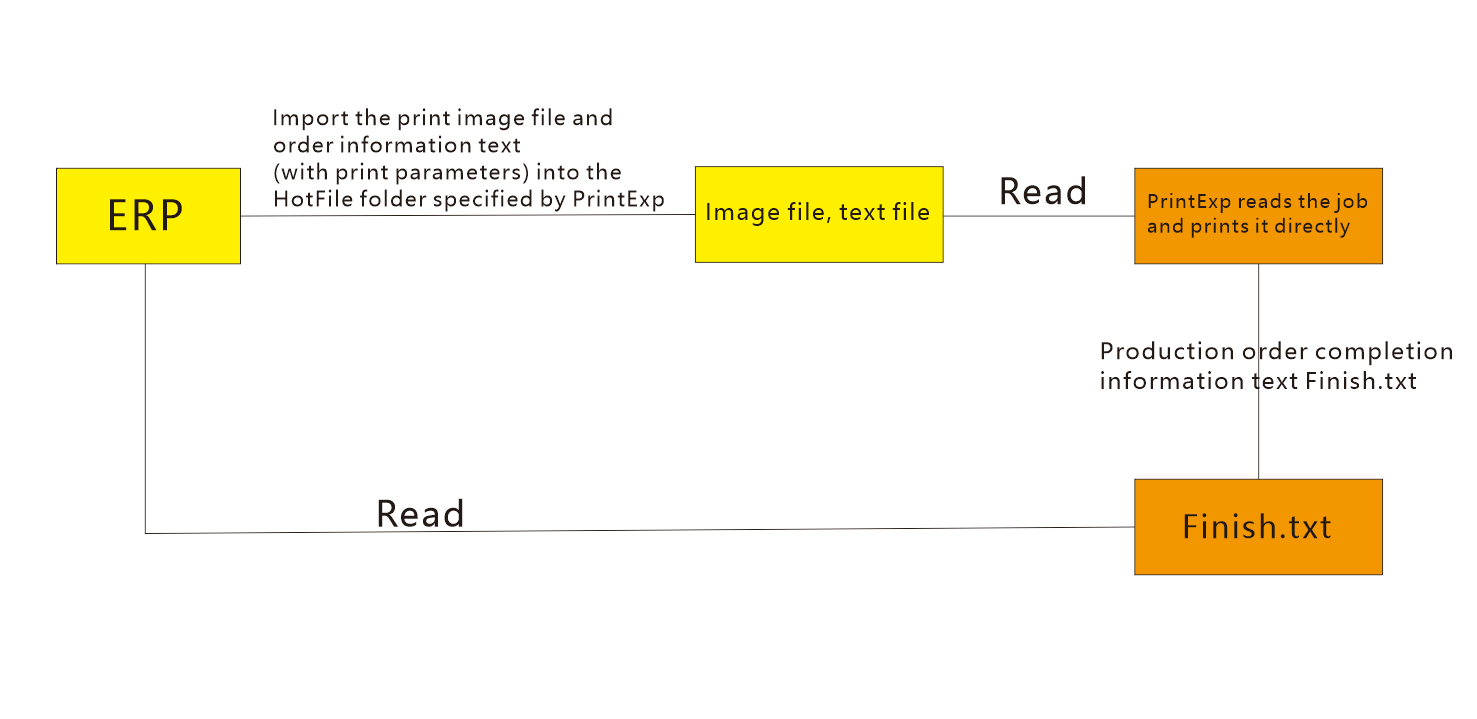

ERP docking port

Help carton factory intelligent production management

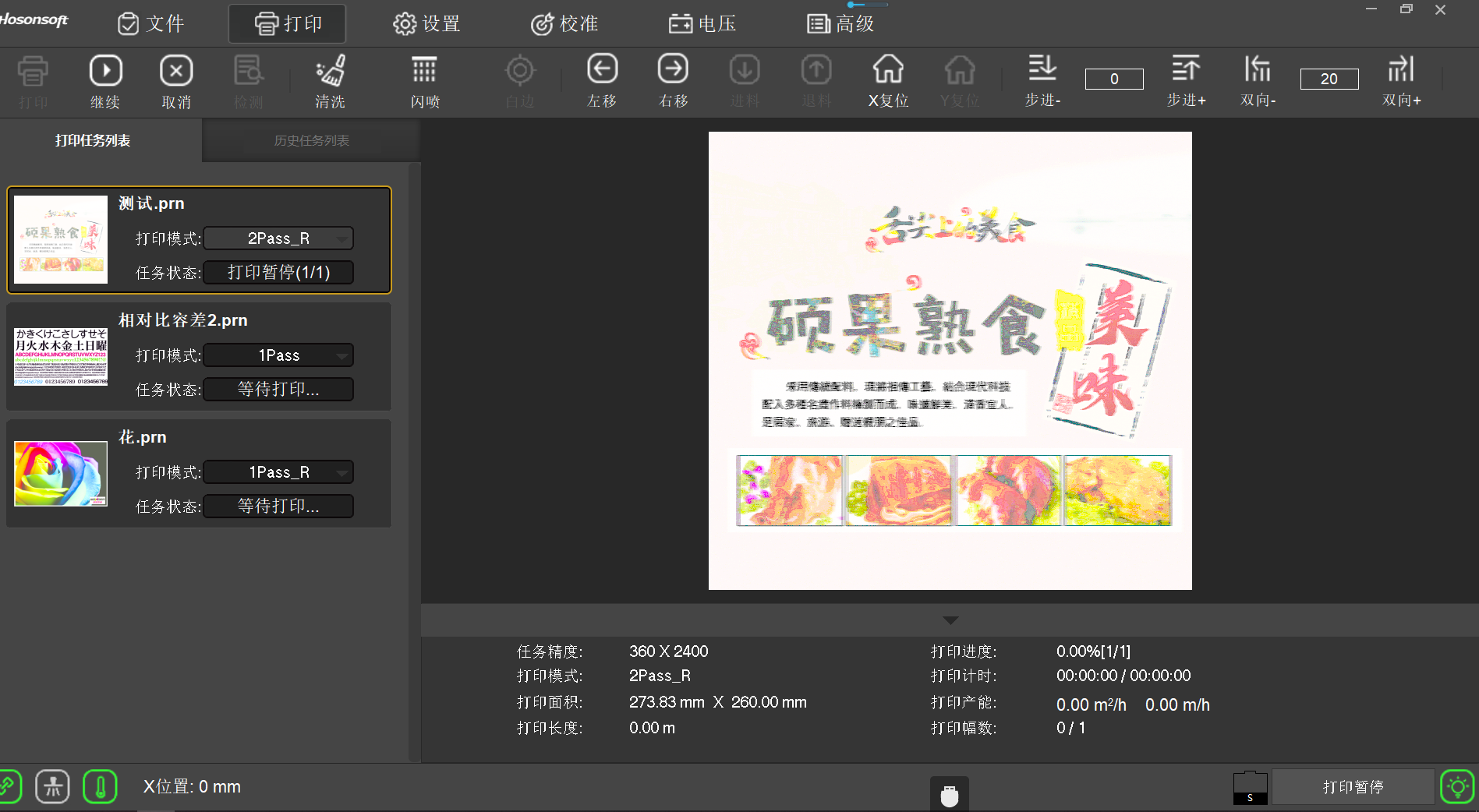

Queue printing

One-click upload of multi-task orders, easy to achieve continuous printing without downtime

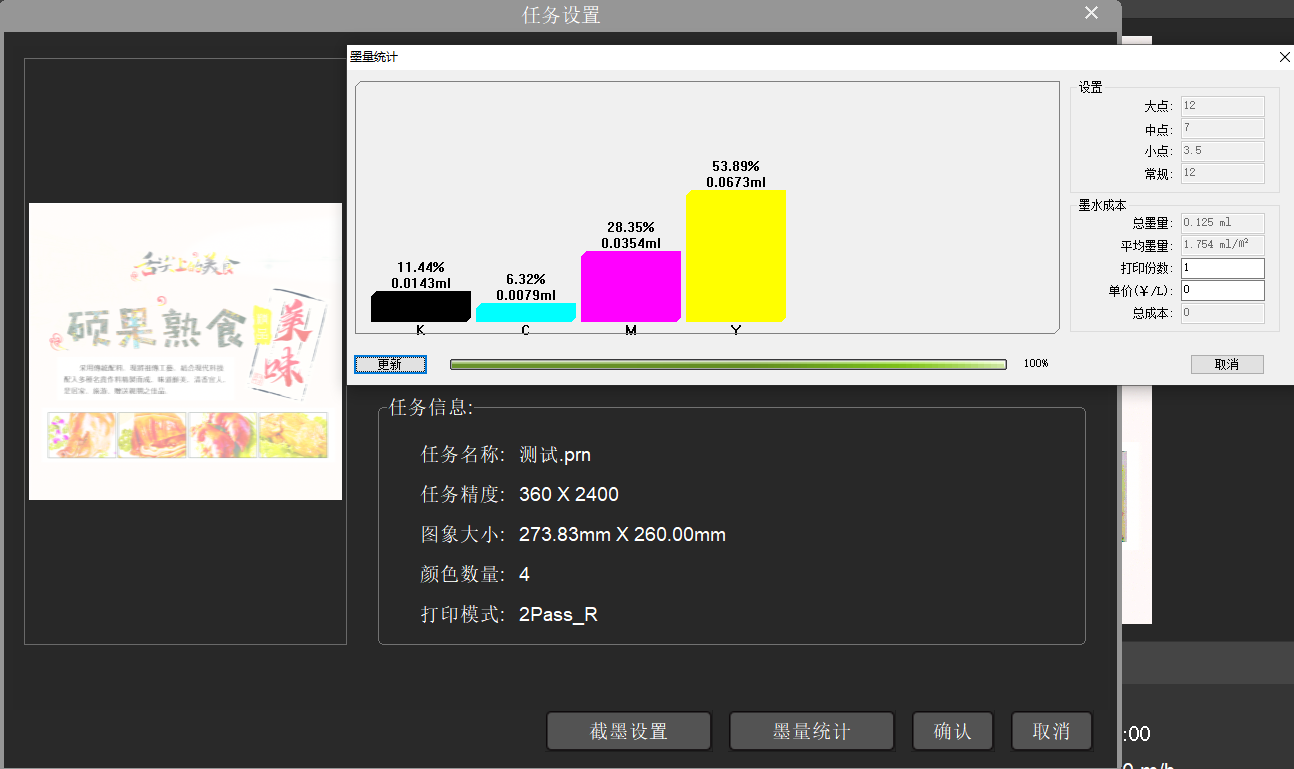

Ink Cost Statistics

Real-time display of computer software, easy calculation of order cost