WD200 Single Pass Industrial Digital Printer

| Model | WD200+ | WD200++ | |

| Printing configuration | Printead | Industrial mirco-piezo printhead | |

| Resolution | ≥600*200dpi | ≥1200*150dpi | |

| Efficiency | 600*200dpi,max 1.8m/s 600*300dpi,max 1.2m/s 600*600dpi,max 0.65m/s |

1200*150dpi,max 2.5m/s 1200*300dpi,max 1.6m/s 1200*600dpi,max 1.0m/s |

|

| Printing width | 800mm-2500mm(can be customized) | ||

| Ink type | Special water-based dye ink, special water-based pigment ink | ||

| Ink color | Cyan,Magenta,Yellow,Black | ||

| Ink supply | Automatic ink supply | ||

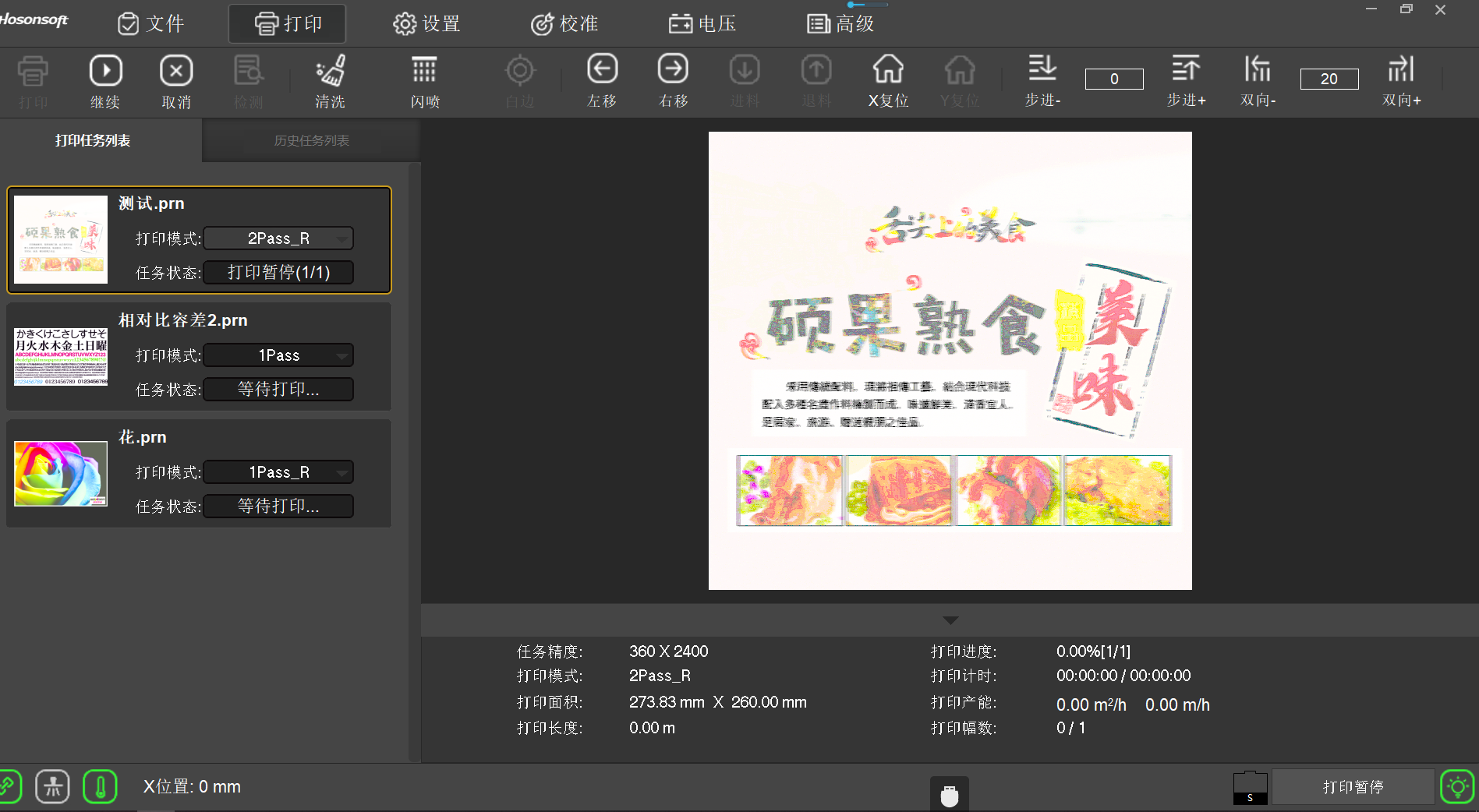

| Operation system | Professional RIP system,professional printing system, Win10/11 system with 64 bit operating system or above |

||

| Input format | JPG,JPEG,PDF,DXF,EPS,TIF,TIFF,BMP,AI,etc. | ||

| Printing material | Application | All kinds of corrugated cardboard (yellow and white cattle board, honeycomb board, etc.), available to print semi-coated board with dryer | |

| Max width | 2500mm | ||

| Min width | 400mm | ||

| Max length | 2400mm under auto feeding,4500mm under manual feeding | ||

| Min length | 420mm | ||

| Thickness | 1.5mm-20mm | ||

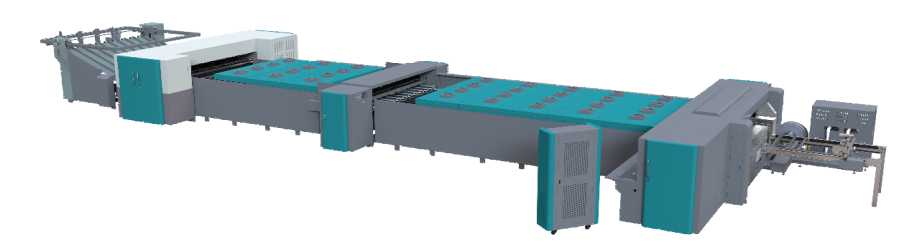

| Feeding system | Automatic leading edge feeding, suction platform | ||

| Working environment | Workplace Requirements | Install compartment | |

| Temperature | 20℃-25℃ | ||

| Humidity | 50%-70% | ||

| Power supply | AC380±10%,50-60HZ | ||

| Air supply | 4kg-8kg | ||

| Power | About 22-24KW | ||

| Others | Machine size | 6645mm×5685mm×2453mm (Please refer to the actual order) | |

| Machine weight | 5500KGS | ||

| Optional | Variable data,ERP docking port | ||

| Voltage stabilizer | The voltage stabilizer needs to be self-configured,request 80KW | ||

| Features | SINGLE PASS | Environmental ink, Single pass high-speed printing, both customized packaging and bulk orders are siutable, production line optional | |

| Advantage | WD200+ use high speed inkjet technology, environmental water-based ink.Higher precision and higher production speed, max can be 1.8m/s with 600*200dpi,actual capacity is 2400~7200 per hour.WD200++ upgrade the technical on the basis of WD200+ corrugated digital printing system which use water-based ink,high precision, good effect and high speed.Maximum printing speed can up to 2.5m/s with 1200*150dpi, and actual capacity is 4500~13000 per hour, do comparable to the traditional printing.

Features |

||

| Features of digital printer (common to all printer) | Revolutionary in world Inkjet technology Print on demand No limit with quantity Variable data ERP docking port Quick-done ability Computer color correction Simple process Easy operation Labor saving No composition change No machine cleaning Low-carbon & environment Cost-effective |

||||

Features of digital printer (common to all printer)

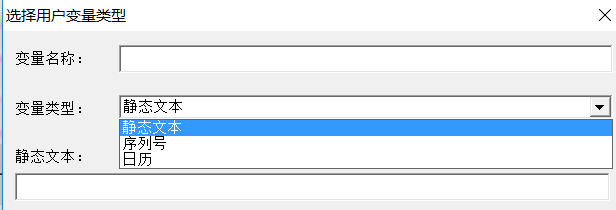

Variable data

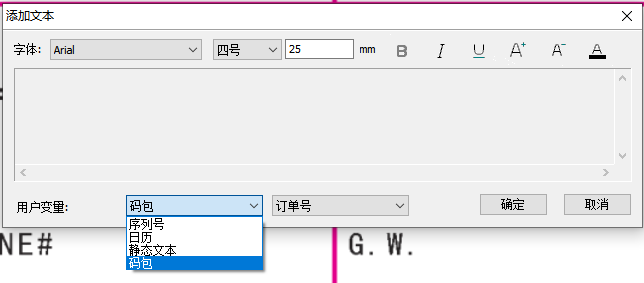

Text variable

Sequence: It can be changed according to user definition, and the set sequence can also be used for variable barcode

Date: Print date data and support custom changes, the set date can also be used for variable barcodes

Text: The text data entered by the user is printed, and the text is generally only used when the mode is text data

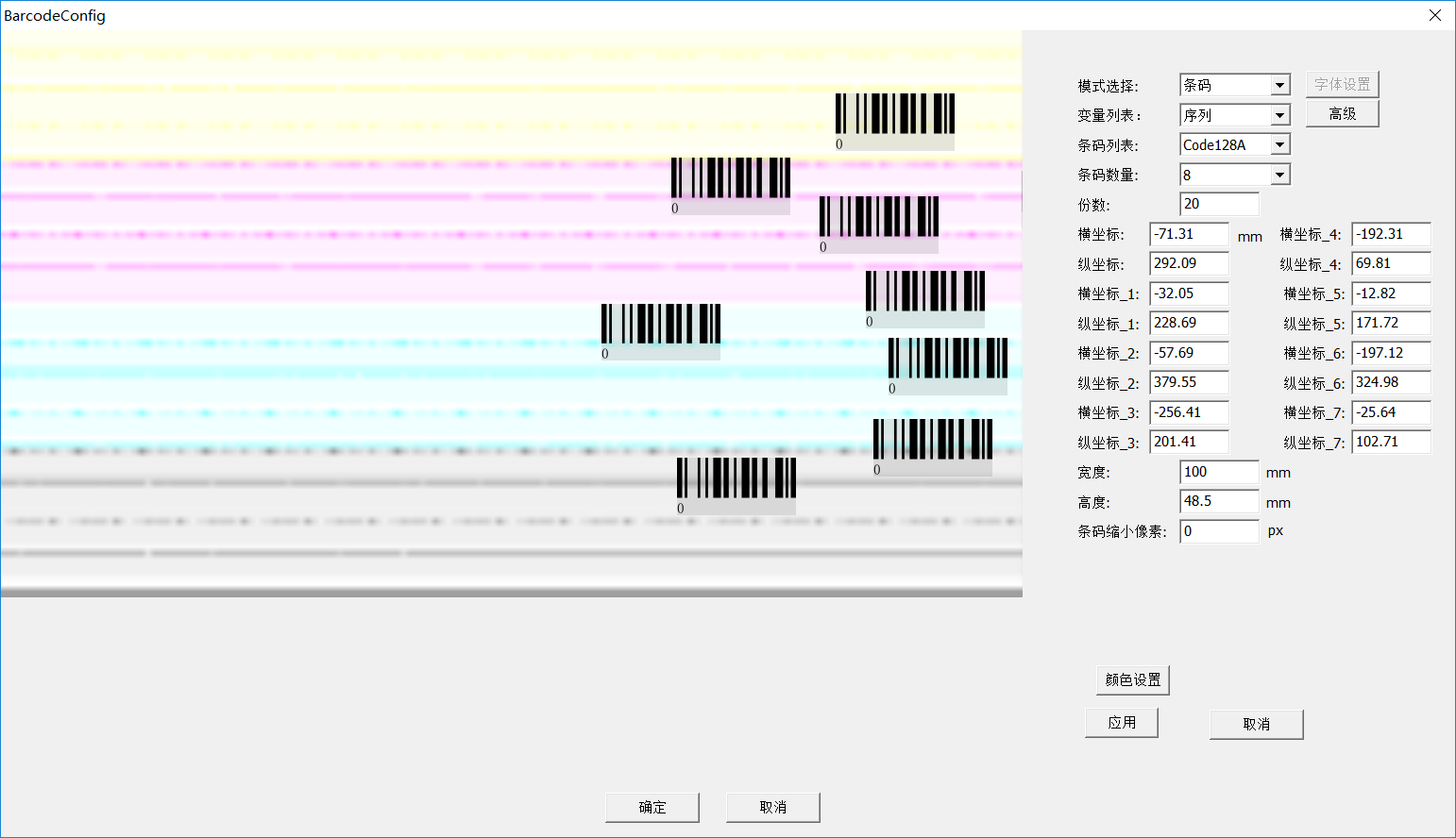

Bar code variable

The current mainstream barcode types can be applied

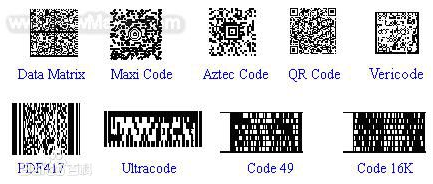

QR code variable

Among the dozens of 2D barcodes at present, the commonly used code systems are: PDF417 2D barcode, Datamatrix 2D barcode, Maxcode 2D barcode. QR Code. Code 49, Code 16K, Code one., etc. In addition to these common two In addition to dimensional barcodes, there are also Vericode barcodes, CP barcodes, CodablockF barcodes, Tianzi barcodes, UItracode barcodes, and Aztec barcodes.

Code package variable

Including: text, barcode, QR code can realize multiple variables on one carton

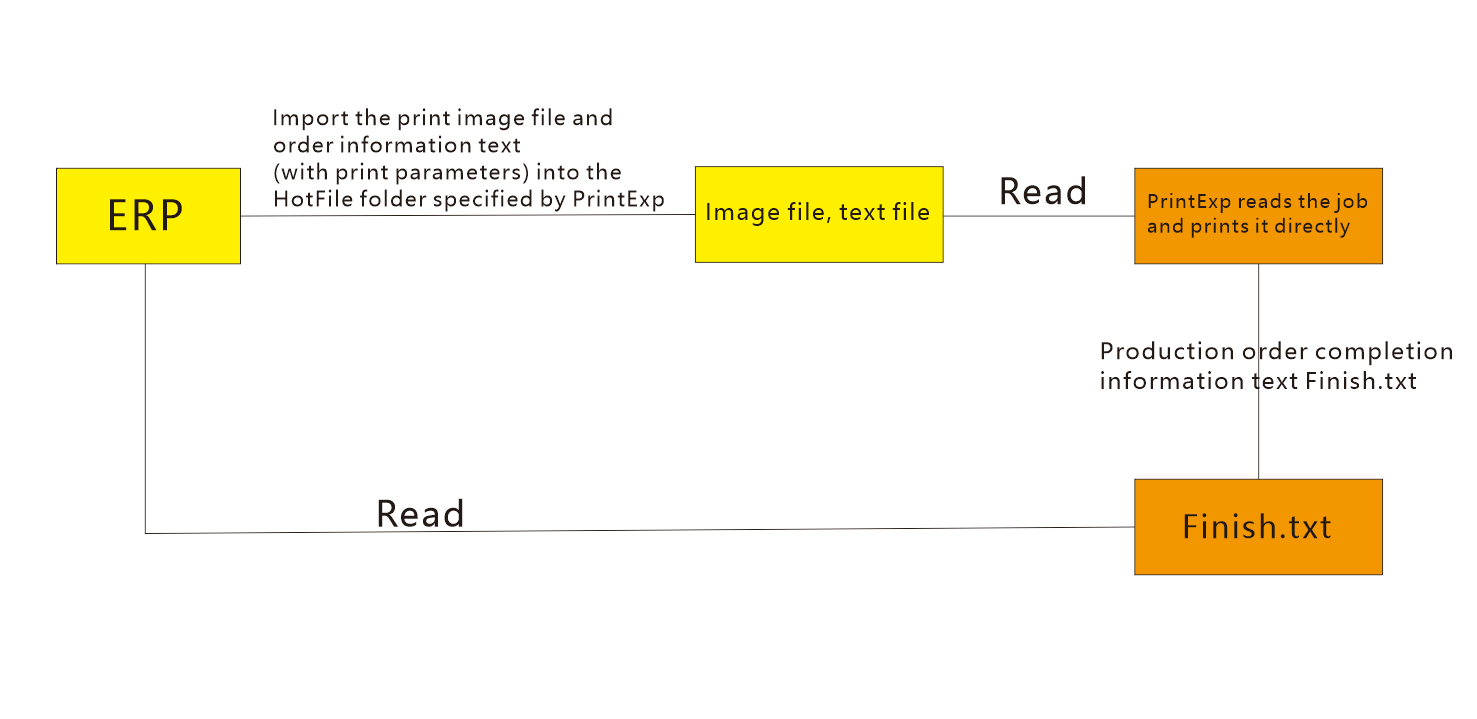

ERP docking port

Help carton factory intelligent production management

Queue printing

One-click upload of multi-task orders, easy to achieve continuous printing without downtime

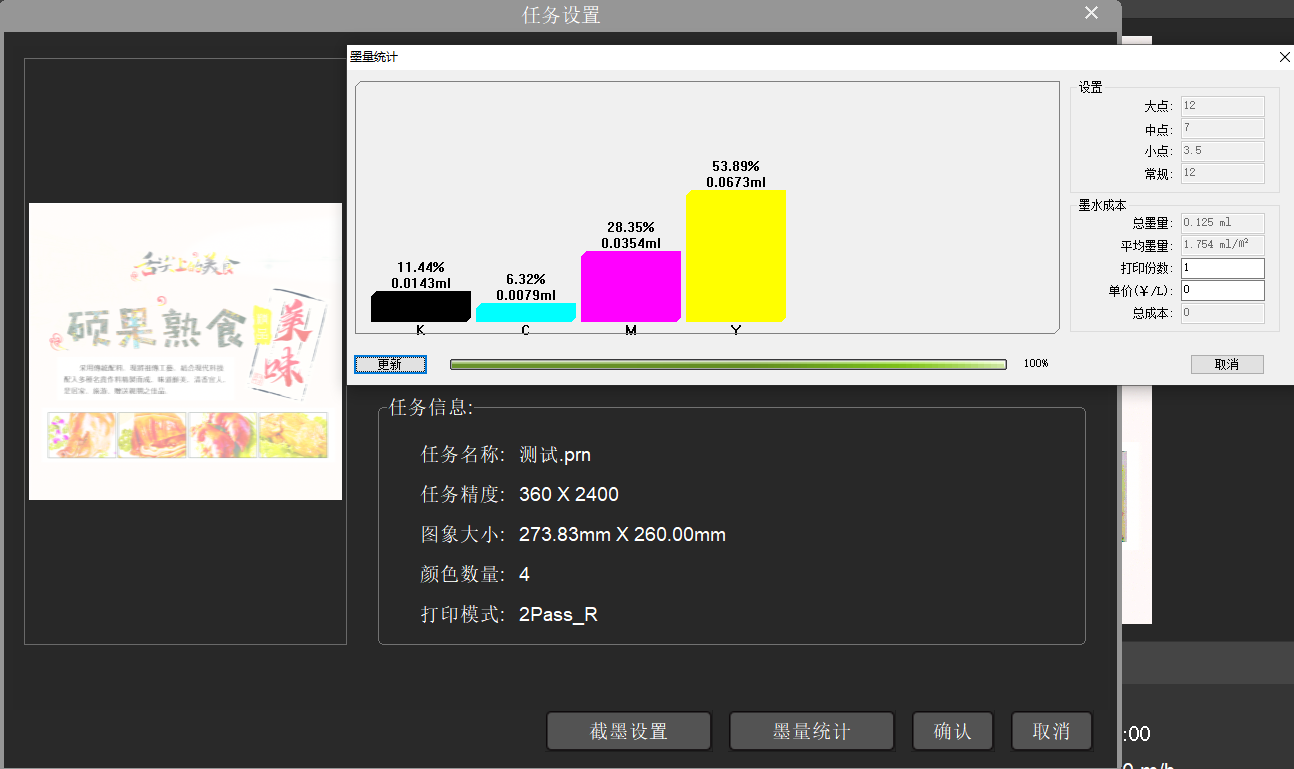

Ink Cost Statistics

Real-time display of computer software, easy calculation of order cost