WD200++ Single Pass Industrial Digital Printer

Features of digital printer (common to all printer)

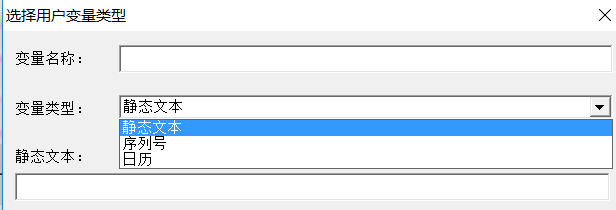

Variable data

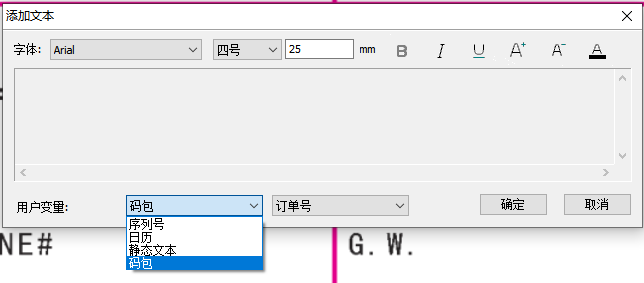

Text variable

Sequence: It can be changed according to user definition, and the set sequence can also be used for variable barcode

Date: Print date data and support custom changes, the set date can also be used for variable barcodes

Text: The text data entered by the user is printed, and the text is generally only used when the mode is text data

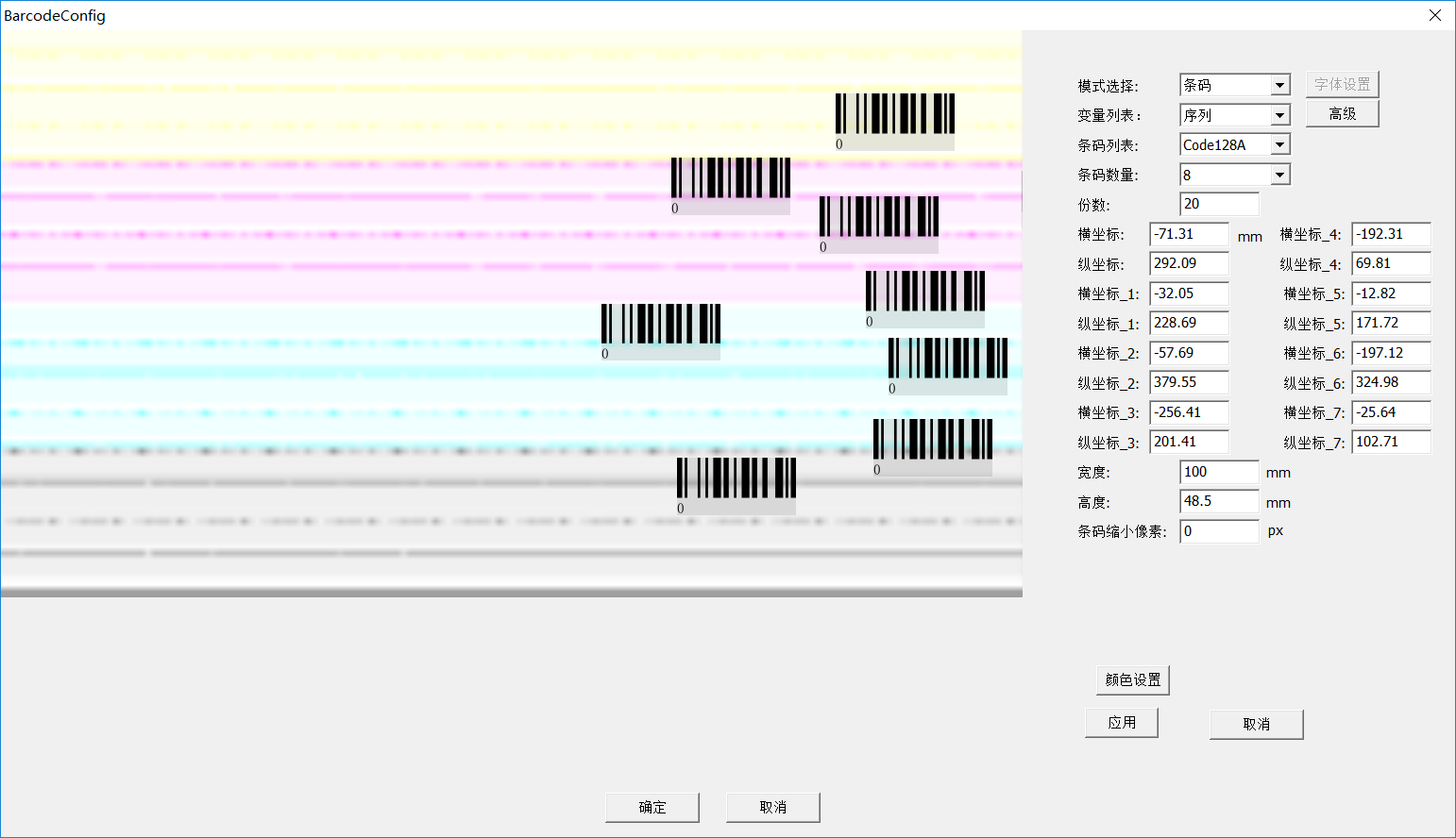

Bar code variable

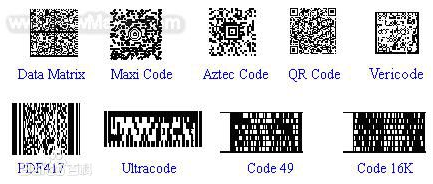

The current mainstream barcode types can be applied

QR code variable

Among the dozens of 2D barcodes at present, the commonly used code systems are: PDF417 2D barcode, Datamatrix 2D barcode, Maxcode 2D barcode. QR Code. Code 49, Code 16K, Code one., etc. In addition to these common two In addition to dimensional barcodes, there are also Vericode barcodes, CP barcodes, CodablockF barcodes, Tianzi barcodes, UItracode barcodes, and Aztec barcodes.

Code package variable

Including: text, barcode, QR code can realize multiple variables on one carton

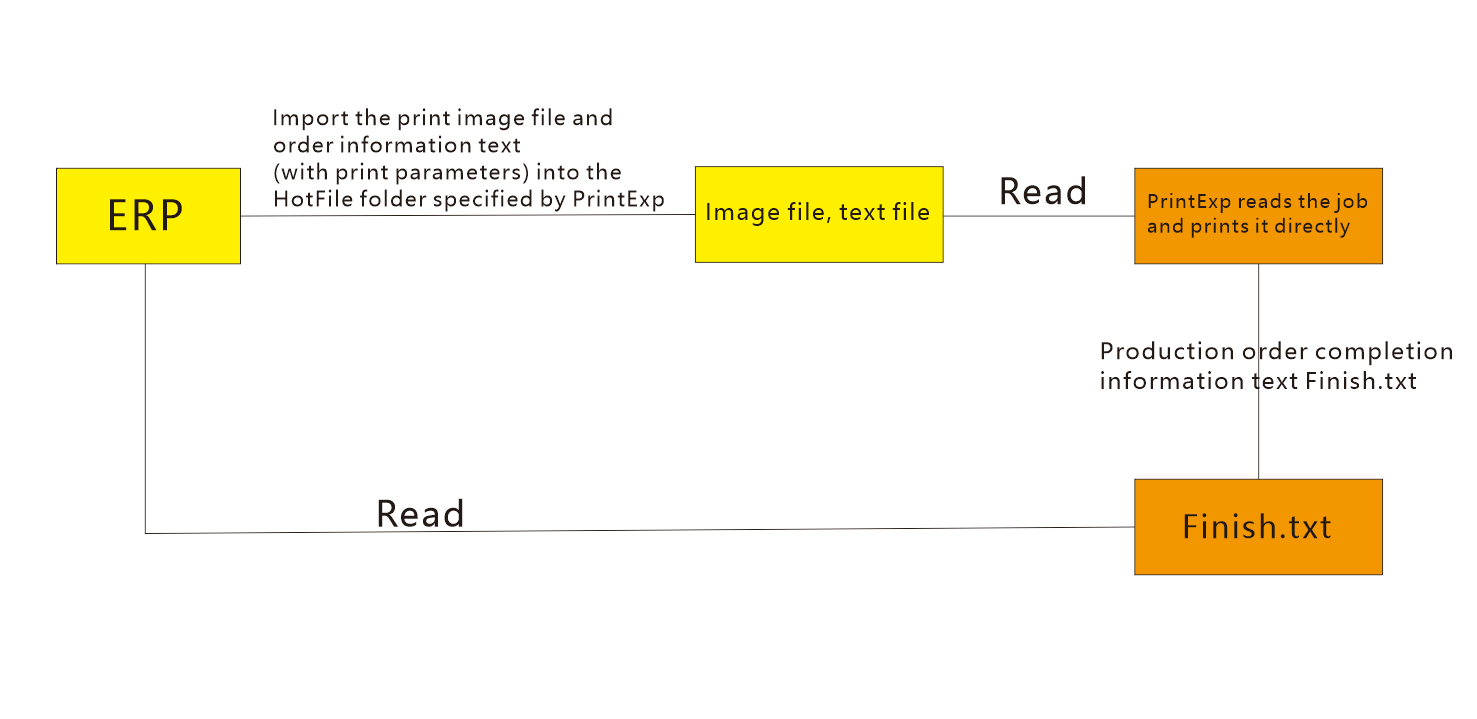

ERP docking port

Help carton factory intelligent production management

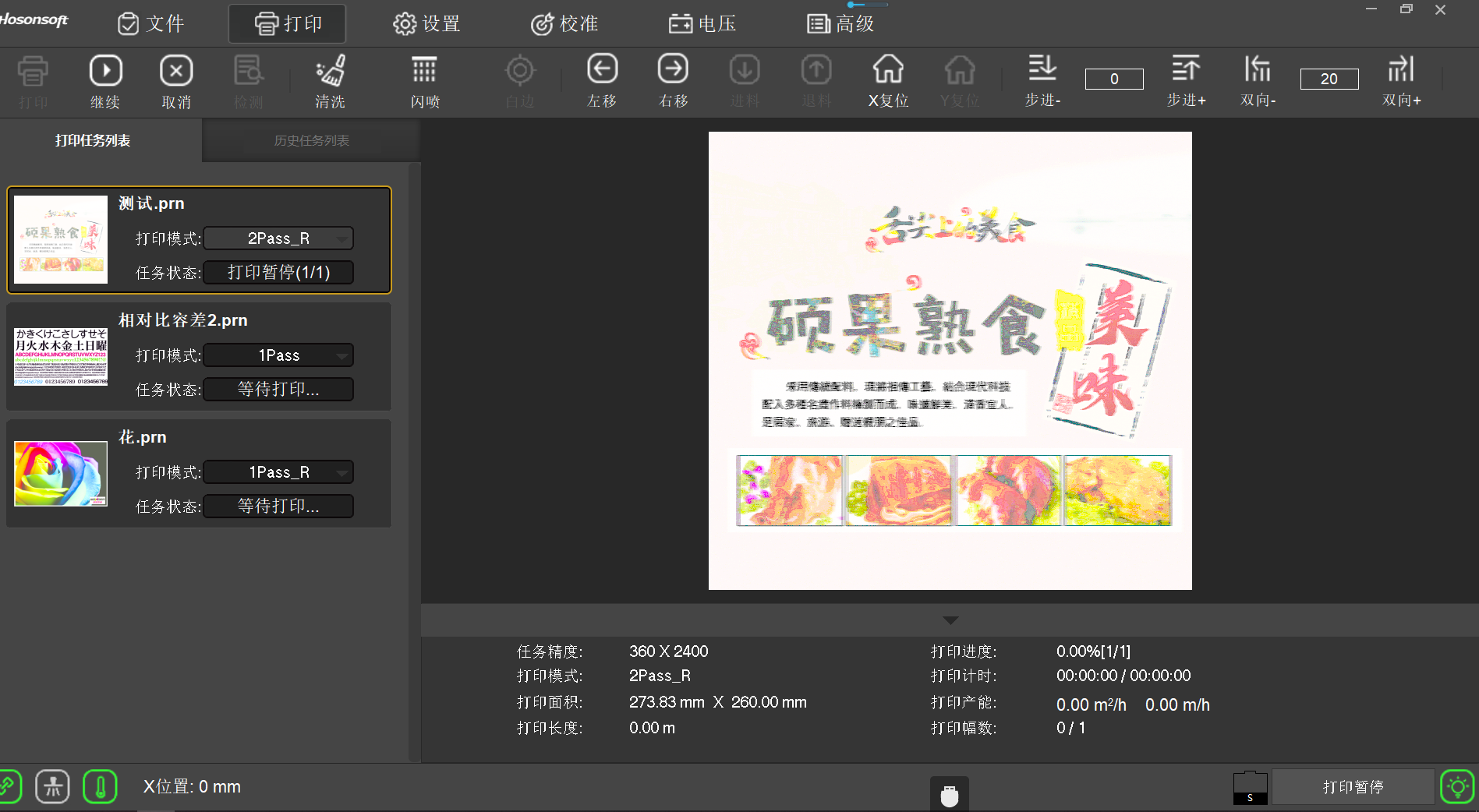

Queue printing

One-click upload of multi-task orders, easy to achieve continuous printing without downtime

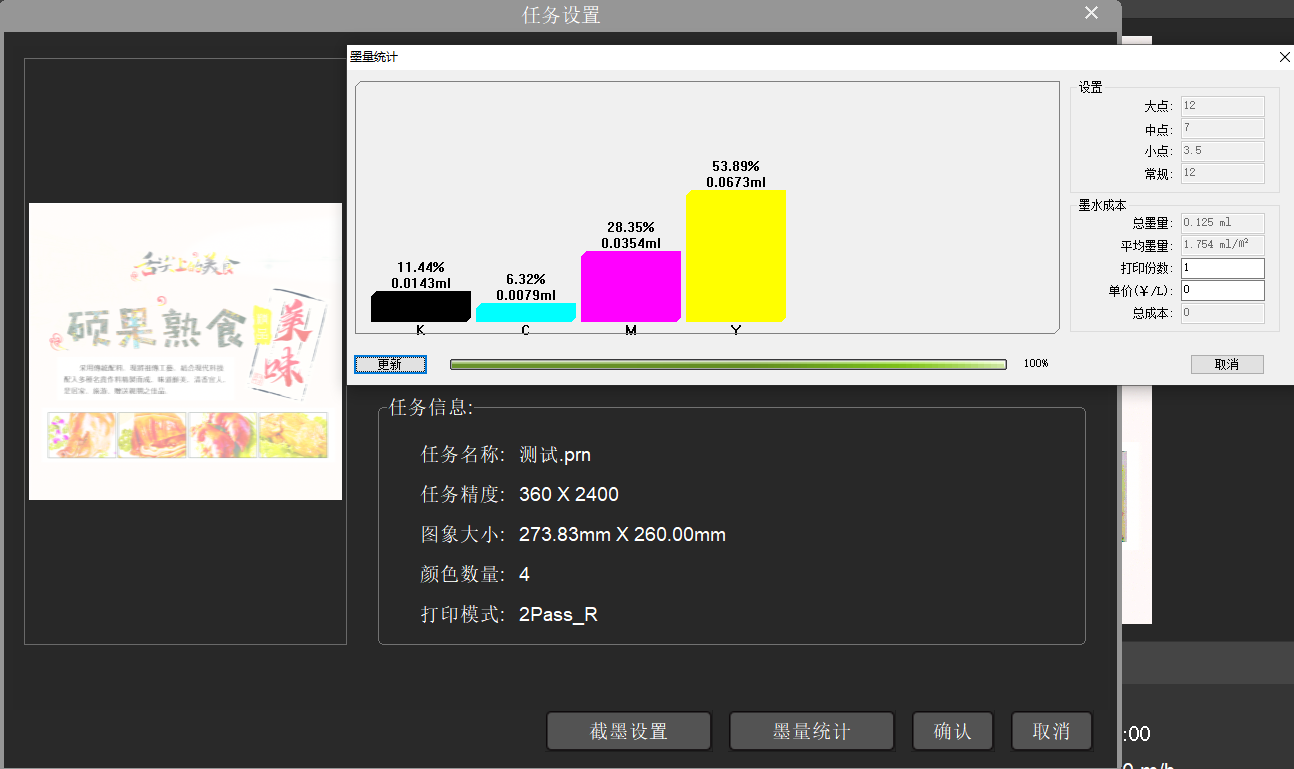

Ink Cost Statistics

Real-time display of computer software, easy calculation of order cost