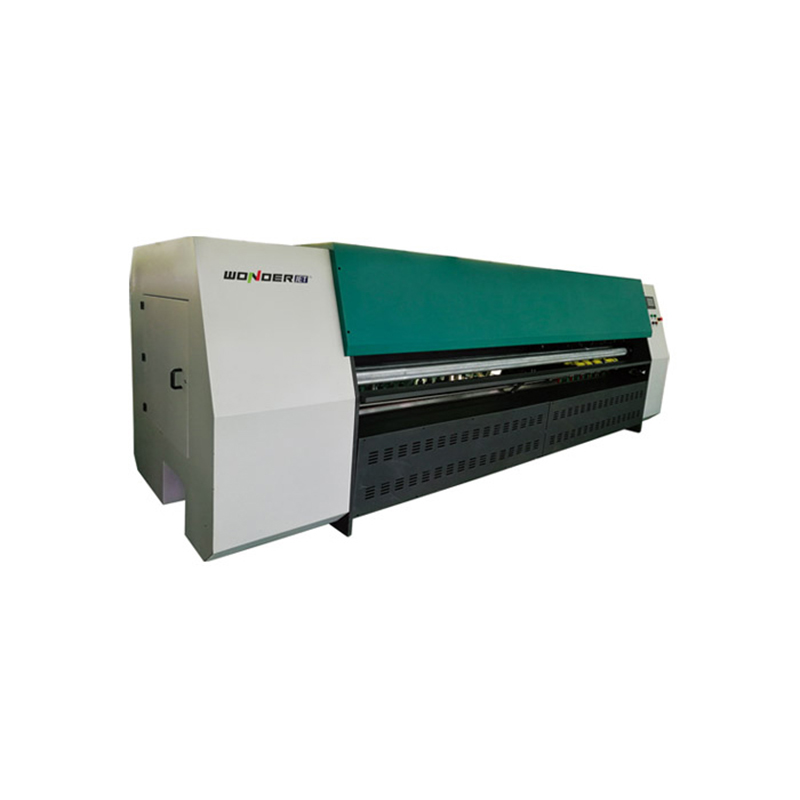

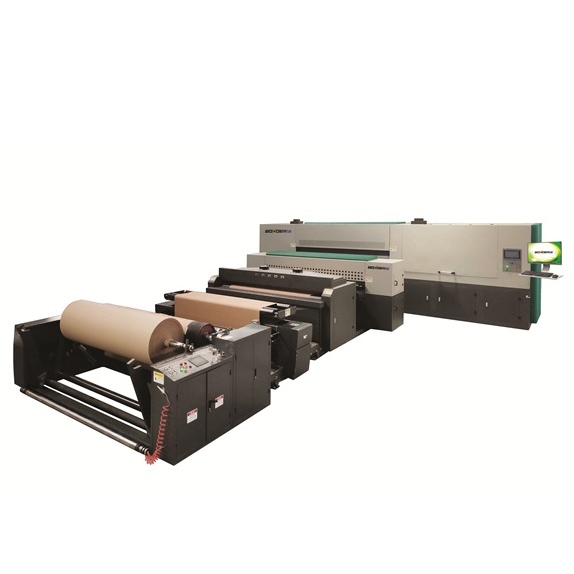

Rapid Delivery for Small Corrugated Box Making Machine - WDUV200-XXX industry single pass roll to roll digital pre-printer for corrugated paper – Wonder

Rapid Delivery for Small Corrugated Box Making Machine - WDUV200-XXX industry single pass roll to roll digital pre-printer for corrugated paper – Wonder Detail:

Product features

1.High speed: Based accuracy 600 lines, printing speed max can be 108 m/min; Optional is 900/1200 lines which can up to 210 m/min;

2.Variable data: The application of variable data technology has realized the “centralized printing, dispersed into cartons” roll to roll pre-printing production, which has more advantages than post-printing, high production speed. And it’s no downtime, seamless order change, 24-hour continuous operation, the corrugated paper formation without loss, greatly improving the quality and efficiency, reduced costs and the loss of time.

3.No Version: Traditional pre-printing system need to produce flexor, chromatography, need washing system, which will produce large amounts of sewage, waste flexor, pollute the environment when replace the varieties., also takes time and cost. but WDR200/WDUV200 pre-printing system use inkjet printing technology,no flexor, no chromatography,no washing,more environmentally,won’t cause those problems and save the cost.

4.Labor: the traditional printing system, from the plate to the printing demands worker with high request and number,the process is cumbersome, time-consuming and labor-intensive, reducing production efficiency . WDR200/WDUV200 pre-printing system use computer plate-making, computer palette and computer save,simple operation, printing on-demand, saving time and labor, high production efficiency.

Applications:

Digital pre-printing for base paper. Included marks,NO., various advertising images, print with single black color or colorful printing are available both.

Specifications:

| Article NO. | WD200-48A++/52A++/64A++/80A++/96A++,etc |

| Printhead | Mirco-piezo hightest printhead |

| Printhead quantity | 48 pieces / 52 pieces / 64 pieces/ 80 pieces/ 96 pieces ( can be customized ) |

| Ink type | Special water-based dye ink, special water-based pigment ink |

| Color model | Cyan,Magenta,Yellow,Black |

| Medium distance | 2mm-4mm |

| Printing resolution | ≥1200*150 dpi |

| Printing efficiency | 1200*150dpi, max speed 2.5m/s; 1200*300dpi, max speed 1.3m/s; 1200*600dpi, max speed 0.65m/s; |

| Material width | 1600mm – 2400mm can be ordered |

| Printing format | X=printhead quantity of single color *53.2mm-15mm |

| Collecting size | Max ΦD1600mm |

| Collecting weight | Max 1800KGS |

| Material thickness | 0.2mm – 1.5mm |

| Dry mode | Connecting with drying channel |

| Standard (optional use) | Drying system, varnish coating system |

| Working environment | 20ºC-25ºC Indoor,Humidity 50%-70% |

| Ink supply | Automatic ink supply |

| Collecting mode | Auto roll to roll collecting system |

| Thermostat system | Thermostat system with patent |

| Operate system | Professional RIP system,professional printing system,Win7 system with 32 bit operating system or above |

| Rated power | About 30 KW power:AC380±10%,50-60HZ |

| Machine size | L*W*H 13680*6582*2700mm |

| Weight | 12500KGS |

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Rapid Delivery for Small Corrugated Box Making Machine - WDUV200-XXX industry single pass roll to roll digital pre-printer for corrugated paper – Wonder , The product will supply to all over the world, such as: Cambodia, Finland, Los Angeles, Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.